VR radial shaft seals

- Pressure resistant radial shaft seals

- Friction-optimized & energy efficient

- Shaft seals for high circumferential speed

- For narrow installation conditions

- For demanding applications

- Radial shaft seals individually manufactured in our factory in Germany

Radial shaft seal

Your challenge: reliable sealing, even under pressure, with minimum energy consumption?

Rely on us as a long-term partner. By using high-performance polymers and intelligent approaches, we work together to optimize your sealing points with sustainable and energy-efficient solutions.

- Advice from development to application

- Individual, precise product customization

- Production from quantity 1

- Made in Germany in our own factory

Technology

- Find out more about the technology here of VR radial shaft seals and the constructive requirements.

About us

- Why do we do what we do? What does our team look like and where are your contact persons?

NEW

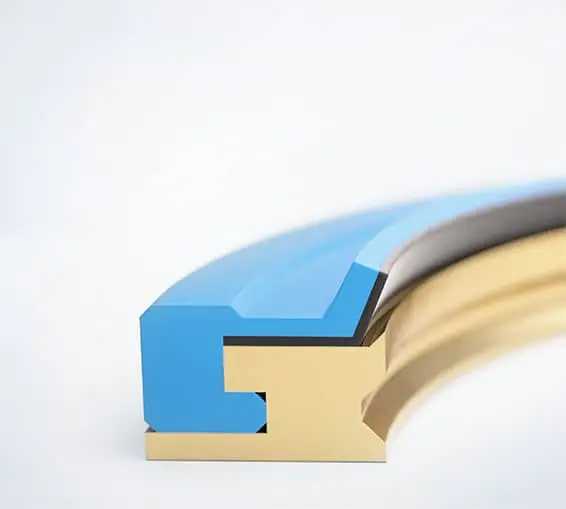

VR Low Friction Seal

This advanced and patented solution merges elastomers with PTFE, leveraging the flexibility of elastomers and the superior frictional qualities of PTFE. By seamlessly integrating these materials, our design guarantees smooth operation and prolonged durability in diverse applications.

Industries

Medical technology

Among other things for

》Centrifuges

》Pumps

》Rotating unions

》Tools

VR radial shaft seals for your challenging applications.

Food industry

Among other things for

food processing eqipment like

》Kneading machines

》Agitators

》Special machines

》Rotating unions

e.g. if the maintenance intervals are to be extended or the temperatures at the sealing points are too high.

Mechanical engineering

Among other things for

》Pumps

》Rotating unions

》Swivel joints

》Robots

》Underwater applications

》Sensors

e.g. if friction is to be minimized or the pressure is too high for conventional seals.

Pharmaceuticals

Among other things for

》Centrifuges

》Pumps

》Rotating unions

》drying devices

Defense

Among other things for

》Sensors

》Gears

》Navy: i.e. side thrusters

》Rotating unions

Naval / Sub-Sea

Among other things for

》Pumps

》Rotating unions

》side thrusters

》Robots

》Underwater applications

》Sensors

Patrick Keulers

Managing Director

Responsibilities: Sales,

Product development

Jacqueline Seidel

Assistant to the management

Responsibilities: Finance, marketing and sales

Successful customer projects

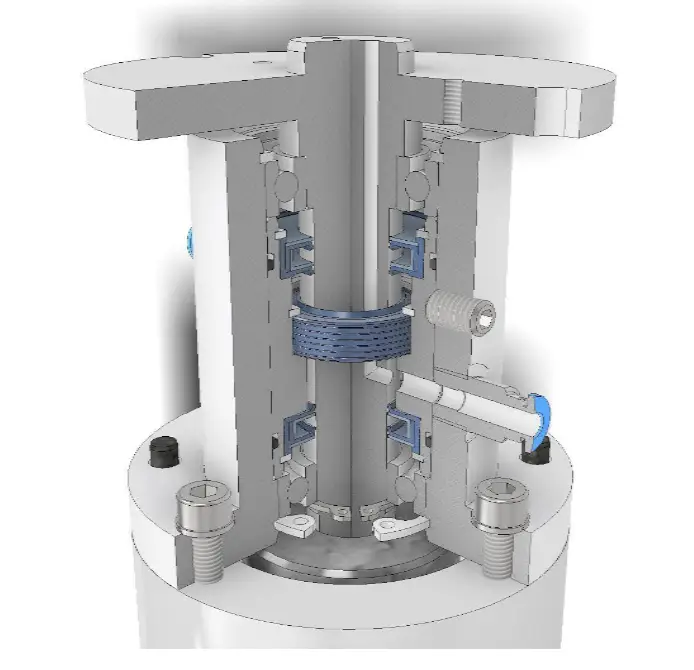

Rotary feedthrough for air and vacuum / Example laser rubber cutting system

For more precise process control, it was necessary to feed both compressed air and vacuum into a rotating device. Ideally, this should be done via a common channel. In addition, the available torque was considerably limited due to a power transmission using a magnetic coupling.

The VR radial shaft seal type SAC proved to be the optimum solution due to its 2 opposing sealing lips and its energy efficiency.

Modern food processing machines with VR radial shaft seals

VR seals are used in machines for food production, especially when conventional rotary shaft seals cause too much friction, smooth surfaces are required or the service life of the current seal is insufficient. Thanks to modern materials, a wide range of applications can be realized.

Machine manufacturer

Miscellaneous

Up to 40 m/s

Up to 50 bar

Become part of our team now!

- Work on our exciting radial shaft seals

- In a young and dynamic team

- with good pay and a range of benefits

Questions and answers

The needs of each company and each machine are different, so prices can vary greatly depending on the work involved. It is therefore highly recommended that you arrange a non-binding consultation to plan your pressure resistand radial shaft seal.

Our company is based in the district of Heinsberg.

We advise the customer on technical queries. If our product is suitable, we will prepare a non-binding offer and, if it is a standard seal, provide a sample.

Commercial inquiries are processed according to the usual processes. The fact that we can produce our rotary shaft seals in very small quantities means that our customers only have to accept low minimum order quantities.

Simply read the size from the seal, take it from the parts list or measure it and send an e-mail to [email protected]. You will receive an offer within 24 hours.

- Leakage in rotating shafts of industrial equipment

- Ingress of dust or dirt into machinery housings

- Seal failure at high temperatures

- Leakage of aggressive chemicals or fluids

- Loss of lubricants in gearboxes and bearings

- Excessive wear on seals at high rotational speeds

- Seal failure under high pressure in hydraulic systems

- Moisture ingress in sensitive electronics

- Sealing under extreme temperature fluctuations

- Protection against corrosion in saline environments

- Ineffective sealing on rough or uneven surfaces

- Challenges sealing in confined installation spaces

- Loss of sealing function due to vibrations and movements

- Seal embrittlement under UV exposure

- Efficiency loss due to high friction of the seal

- Premature wear in abrasive media

- Ingress of foreign particles in outdoor machinery use

- Leakage due to insufficient chemical resistance

- Long replacement intervals of radial shaft seals in hard-to-reach machine components

- Need for environmentally friendly sealing materials without PFAS

Our Catalogue

Explore our range of energy efficient radial shaft seals for a variety of demanding applications. Our technical catalogue provides a detailed insight into solutions for your requirements. Download the catalogue now to access specifications, application notes and more.