Test of Radial Shaft Seals SAB 12 28 for IP69k Certification

Introduction

This white paper presents the results of our in-house tests for the IP69k certification of SAB radial shaft seals. These tests confirm the high quality and reliability of our products under extreme conditions.

Product Specifications

Our SAB radial shaft seal, made from food-grade fluorocarbon rubber (FKM-19), is designed for demanding applications requiring extreme resistance to high temperatures, chemical influences, and mechanical stresses. Other elastomers in our range meet the same high standard.

Test Methodology and Conditions

The IP69k certification requires seals to withstand extreme water pressure and high temperature. Our tests were conducted under the following conditions:

- Water Pressure: 100+ bar

- Water Temperature: 80°C

- Test Duration: 30 seconds per test cycle

- Test Angles: 4 different angles to ensure full coverage

- Test Setup: A high-pressure washer was mounted on a special structure, allowing for 4 angles (0°, 30°, 60°, 90°) and maintaining the specified distance of 10-15cm.

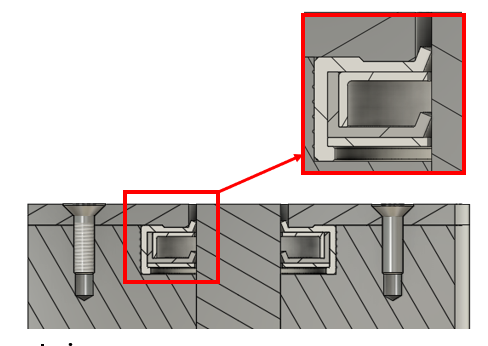

Protective Cover

protective cover consists of a round plate with a central hole for the shaft. The distance from the shaft to the protection hole is 0.5 mm on each side. This device was designed to prevent the direct impact of the water jet on the seal, ensuring the seal’s integrity.

Test result

Tests with Protective Cover

The SAB 12 28 radial shaft seal successfully withstood the conditions required for IP69k certification when the protective device was used. The protective cover prevented the water jet from directly hitting the seal, leading to a successful seal.

- Result: Successful

- Leakage: 0%

- Protective Device: Round plate with central opening and 0.5 mm distance to the shaft

Tests without Protective Cover

Without the protective cover, the seal could not withstand direct water spray. This highlights the necessity of the protective device to meet the IP69k requirements.

- Result: not successful

- Leakage: 100%

Conclusion

Our SAB radial shaft seals provide a reliable solution for applications requiring IP69k certification, provided they are used with the appropriate protective cover. These findings are based on the successful performance of SAB 12.28.7-193 seals under extreme conditions. The protective cover is crucial for compliance with IP69k standards, ensuring the integrity and longevity of our seals.