Introduction

Rotary unions, also known as rotary joints, play a critical role in transferring media like liquids, gases, or electrical signals between stationary and rotating components. These components are essential across industries such as manufacturing, chemical processing, oil and gas, and food production.

The performance and reliability of rotary unions heavily depend on the quality of the seals they use. Advances in sealing technology, such as the development of VR seals, provide enhanced performance by reducing friction and offering pre-lubrication options, making them invaluable in diverse industrial applications.

The Importance of Seals in Rotary Unions

Seals are fundamental to ensuring leak-free operation and consistent media transfer in rotary unions. Traditional seals, while effective in certain applications, often fall short in meeting modern demands for higher performance, durability, and reduced maintenance.

VR seals address these challenges by offering innovative solutions that improve efficiency and longevity, particularly in high-demand environments.

Introducing VR Seals

VR seals are precision-engineered rotary shaft seals designed to minimize friction between rotating and stationary components. Their advanced design reduces wear and extends the lifespan of both the seals and the rotary unions they support.

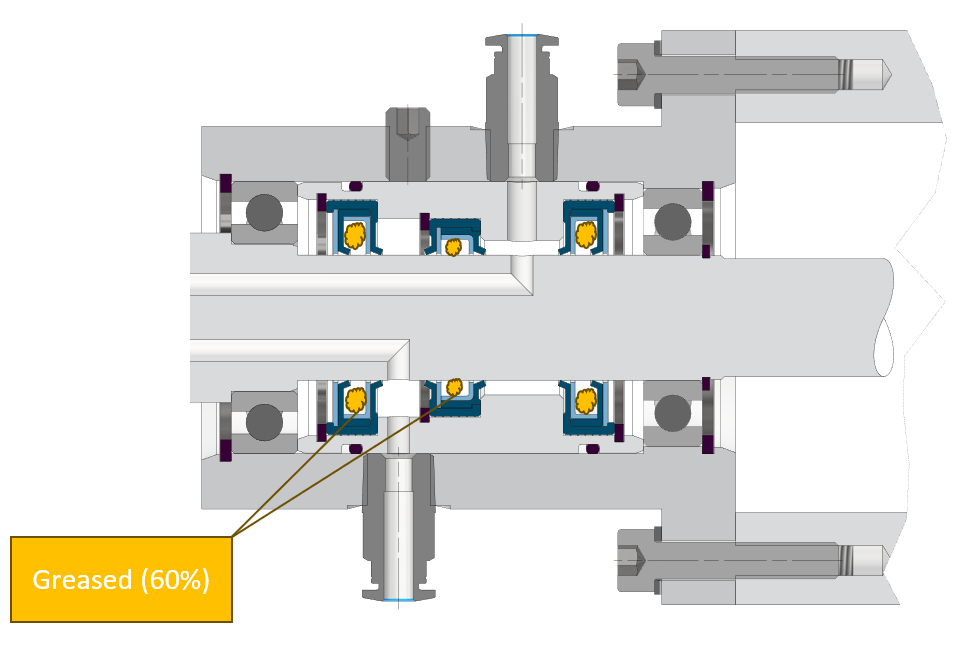

A key feature of VR seals is the option for pre-lubrication. This ensures optimal performance from the start, reduces initial setup time, and minimizes maintenance requirements over time.

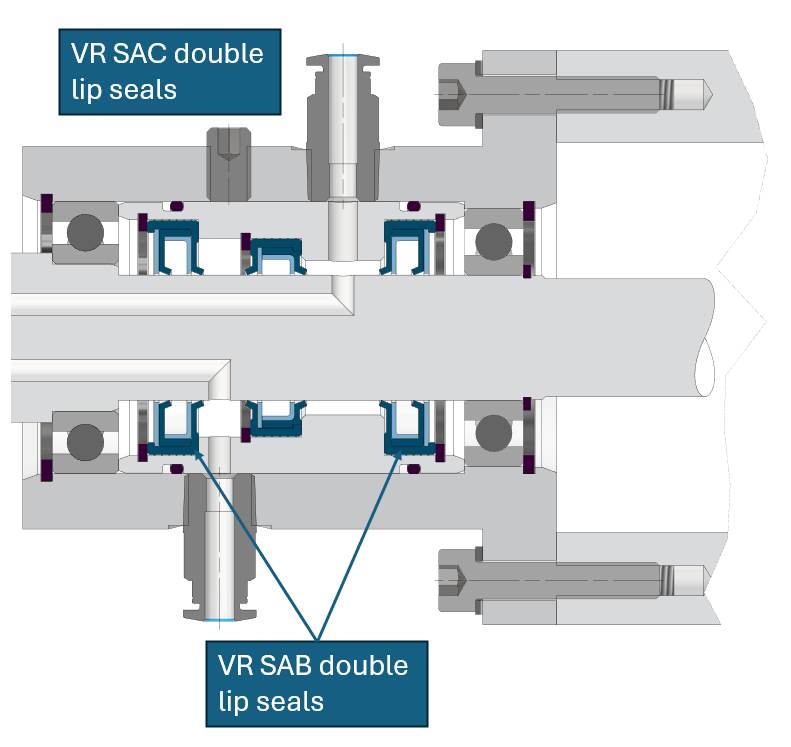

Figure 1 – rotary union equipped with VR seals

Key Benefits of VR Seals in Rotary Unions

- Friction Reduction:

VR seals minimize friction, leading to less wear and extended operational life for both the seals and the equipment. - Pre-Lubricated Option:

The availability of pre-lubricated VR seals simplifies installation, ensures immediate optimal performance, and reduces maintenance intervals. - Enhanced Durability:

Manufactured from advanced materials, VR seals are built to withstand demanding conditions, such as extreme temperatures, pressure, and exposure to aggressive chemicals. - Versatility:

VR seals can be customized for a wide range of applications across industries, including automotive, aerospace, food and beverage, chemical processing, and petrochemical. - Improved Energy Efficiency:

By reducing friction, VR Low Friction Seals help save energy, aligning with sustainability goals and reducing operational costs.

Applications of Rotary Unions with VR Seals

The integration of VR seals into rotary unions opens up new possibilities for various industries:

- Automotive Manufacturing:

- VR seals excel in high-speed rotary unions for fluid transfer, ensuring reliable performance and extended service life.

- Chemical and Pharmaceutical Industries:

- Resistant to harsh chemicals and high temperatures, VR seals minimize downtime and ensure safe operations.

- Food and Beverage Production:

- Pre-lubricated VR seals meet stringent hygiene standards while offering long-lasting and contamination-free performance.

- Oil and Gas Exploration:

- Withstanding corrosive substances and extreme pressures, VR seals ensure consistent operation in challenging environments.

Advancing Rotary Union Technology with VR Seals

The integration of VR seals in rotary unions marks a significant advancement in fluid dynamics and mechanical engineering. Reduced friction, enhanced durability, and pre-lubricated options make VR seals a superior choice for industrial applications requiring efficiency, reliability, and long service life.

To learn more about VR seals and their applications, download our detailed catalog: VR Dichtungen Catalog.

For customized solutions or technical support, feel free to reach out to our team. Let’s optimize your rotary unions with cutting-edge sealing technology!