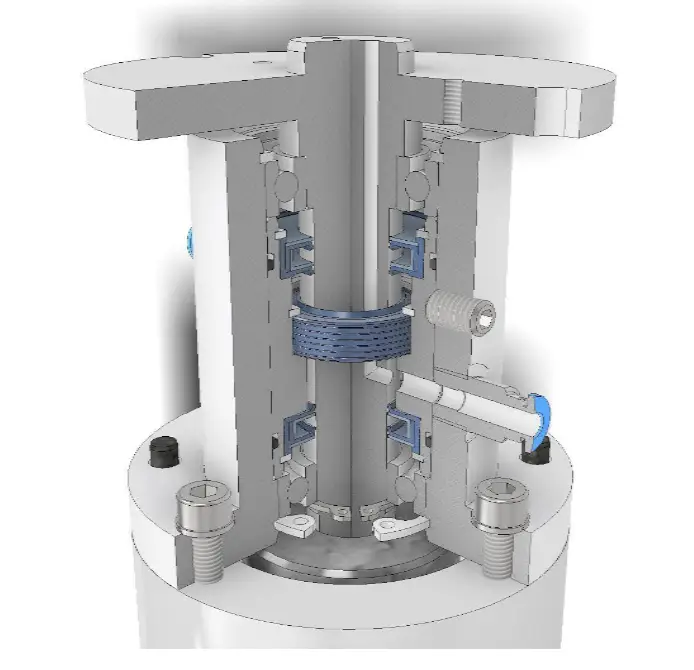

Radial Shaft Seals by VR Dichtungen for stainless steel shafts

Choosing the right sealing solution is crucial for the performance and longevity of technical systems. When it comes to stainless steel shafts without hardening, engineers face specific challenges. The radial shaft seals from VR Dichtungen offer an innovative solution specifically designed for these requirements – with clearly defined application limits and practical optimization options.

Challenges with Unhardened Stainless Steel Shafts

Stainless steel shafts are widely used in industries such as food processing, medical technology, and the chemical industry due to their corrosion resistance. However, unhardened stainless steel shafts present the following challenges:

- Increased susceptibility to wear: Standard seals can damage the soft surface of the shafts.

- High friction: Traditional seals increase energy consumption and generate more heat.

- High costs for post-treatment: Processes like nitriding, chrome plating, or other hardening treatments are expensive and time-consuming.

Limitations: When Stainless Steel Shafts Without Hardening Are Suitable

Unhardened stainless steel shafts are not suitable for all applications. Radial shaft seals from VR Dichtungen deliver optimal performance under the following conditions:

- Moderate pressure and rotational speed

- Suitable for applications with moderate loads: pressure ≤ 0.6 MPa and rotational speed ≤ 5 m/s.

- Non-abrasive media

- Ideal for clean media such as water, oils, or air. Abrasive media can damage the shaft surface and shorten seal lifespan.

- Optimized shaft surface

- Roller burnishing the sealing surface is a cost-effective step to improve hardness and surface roughness values. This method significantly extends the seal’s lifespan.

- Alternative for demanding conditions

- For applications with high pressures, high speeds, or abrasive media, non-corrosive shaft sleeves are a practical solution. These effectively protect the shaft surface and extend system lifespan.

Why VR Radial Shaft Seals Are Ideal for Stainless Steel Shafts

The radial shaft seals from VR Dichtungen are specifically designed for unhardened stainless steel shafts. They offer several advantages:

- Preservation of the shaft surface

- Precisely tensioned radial and tangential sealing lips prevent destructive wear marks.

- No post-treatment required

- Shaft hardening is unnecessary, saving time and costs.

- Reduced friction and energy consumption

- The innovative design minimizes friction, improving the energy efficiency of your application.

- Long service life under moderate conditions

- These seals are highly durable when the defined application limits are observed.

Typical Application Areas

VR radial shaft seals are indispensable in many industries, especially where unhardened stainless steel shafts are used:

- Food and pharmaceutical industries

Perfect for hygienic applications such as mixers, pumps, and packaging machines. These seals are easy to clean and corrosion-resistant. - Medical technology

Ideal for precision devices such as pumps, centrifuges, instruments, and sensors. Suitable also for capillary tubes with a minimum diameter of 0.6 mm. - Underwater technology and marine applications

Excellent for applications such as ship shafts or underwater robotics. These seals offer high corrosion resistance.

A Sustainable Solution with Added Benefits

Our VR radial shaft seals stand for innovation and sustainability:

- Recyclability: No chemical bonds between metal and rubber components, enabling easier disposal.

- Energy savings: Reduced friction losses decrease energy consumption in your application.

- Use of recycled materials: The design allows for a high proportion of recycled materials without compromising quality.

Conclusion

The radial shaft seals from VR Dichtungen are the optimal solution for unhardened stainless steel shafts – provided that pressure, rotational speed, and media properties stay within the recommended limits. For more demanding conditions, shaft sleeves offer an effective alternative. With their reliability, durability, and sustainable design, they are a forward-thinking choice for many industries.