Technology

VR lip seals

A rotary shaft seal seals a rotating shaft against a housing. Due to its special design, the VR seal ring is suitable for high circumferential speeds and high pressure loads..

Sealing mechanism of the VR seals

The operating mechanism of the springless VR radial shaft seal is based on rubber-elastic membrane bodies being precisely tensioned over support bodies made of stainless steel or other metals. The subsequent sealing lip, arranged at an oblique angle, can point either outward or inward depending on the installation position and the direction of the medium to be sealed.

This mechanism relies on the radial and tangential pre-tensioning of the membrane body, resulting in a spring-like effect between the membrane body and the sealing lip. Consequently, both radial and tangential forces acting on the sealing lip are balanced in rotating shafts, thereby reducing resulting shear stresses. Vibrations as well as static and dynamic runout deviations are directly absorbed in the area of the sealing lip. The design of the seal minimizes the partial lifting of the sealing lip in rotating shafts and the associated pumping effect.

Comparative measurements have shown that the VR seal requires only 1/3 to 1/4 of the radial force compared to the worm spring-supported sealing element while maintaining the same sealing performance. This contributes positively to the energy efficiency of modern products.

VR advantages

- Pressure resistant

- Friction-optimized & energy efficient

- For high circumferential speed

- For narrow installation conditions

- For demanding applications

- Reduced so called pumping effect due to tangential and radial pre-tensioning

- Reliable sealing on unhardened and stainless steel shafts*

- No damaging wear tracks*

- No post-treatment of the shaft material required, such as hardening, nitriding, hard chrome plating, or additional running sleeves*

*Applies only under corresponding operating conditions; please consult for higher pressures and circumferential speeds or with abrasive media.

VR standard seals

|

Property

|

Unit

|

Value

|

|---|---|---|

|

Vmax*

|

m/s

|

40

|

|

Pmax*

|

MPa

|

1.5

|

|

Temperature range**

|

°C

|

-50°C - 260°C

|

|

Temperature range**

|

°F)

|

-58°F - 500°F

|

* not simultaneously

** Choose corresponding elastomer. Contact us for challenging applications

|

Property

|

Unit

|

Value

|

|---|---|---|

|

Vmax*

|

m/s

|

40

|

|

Pmax*

|

MPa

|

15

|

|

Temperature range**

|

°C

|

-50°C - 260°C

|

|

Temperature range**

|

°F)

|

-58°F - 500°F

|

* not simultaneously

** Choose corresponding elastomer. Contact us for challenging applications

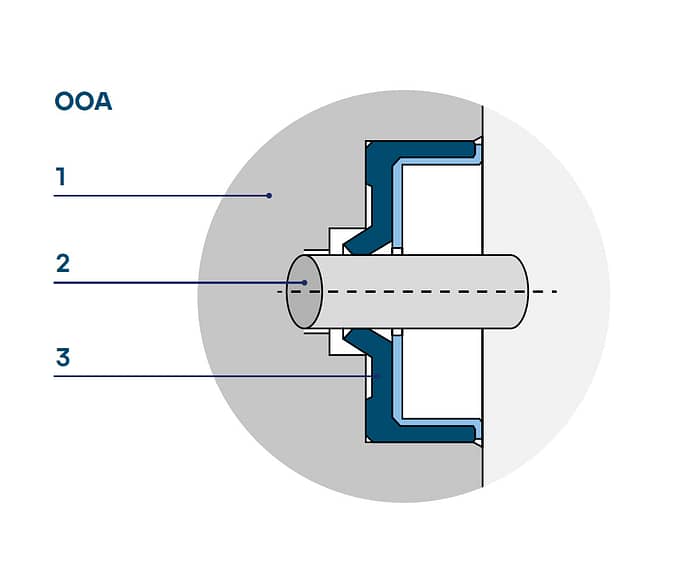

Sealing Environment

A complex system of mutually influencing variables has an effect on the sealing behavior and service life.

(1) Housing

- Surfaces

- Tolerances

- Material

- Center offset to the shaft

(2) Shaft

- Surfaces

- Diameter

- Speed

- Eccentricity

- Material

- Axial movement

(3) VR sealing ring

- Radial force

- Construction and tolerances

- Material

- Hardness

- Wear resistance

- Frictional properties

- Resistance to swelling and shrinkage

Medium

- Chemical effects

- Viscosity

- Pressure

- Decomposition products

- Lubricity

Environment and operating mode

- Temperature

- Dust and dirt

- Cleaning agents

- Running and standstill periods

Elastomer

Rubber is a very special material. Above all, its high resilience (elasticity) stands out here. VR seals make particular use of this property thanks to their design.

Elastomers consist of a long chain of repeating monomers. Such a chain-like arrangement is called a polymer. In elastomers, this twistability is so pronounced that the molecules twist together to form a so-called polymer ball (rubber elasticity). This effort is merely the result of the rotational movement along the chain in completely random directions. The arrangement of the individual atoms of the chain around the center of the molecule corresponds to a Gaussian distribution.

If a polymer is stretched by tensile stress, the chains align themselves preferentially in the direction of the load. The elastomer is therefore stretched. As soon as the tensile stress is removed, the chains begin to rotate randomly again, in the course of which they again adopt the statistically based Gaussian distribution. The chains “relax” and the elastomer contracts again. VR Dichtungen offers you a very wide range of elastomers, from NBR for standard seals to the latest high-performance materials, also for FDA/food requirements.